Join the rest of the community that depends on Pine Research Instrumentation Rotating Cylinder Electrode systems. Our 15 mm RCE electrode system is the trusted tool to perform corrosion analysis, namely screening of corrosion inhibitors. Identifying and selecting all the required components of a complete RCE electrochemical corrosion screening system can be a daunting task. We have helped ease that burden by organizing RCE bundle options with several options to suit your laboratory needs. A complete RCE system requires a potentiostat, electrode rotator, rotating cylinder electrode, cell with all accessories, counter electrode, reference electrode, and common accessories such as Luggin tubes and gas sparge/purge tubes.

The corrosion cell included with this bundle is the 1 liter basic cell with drain valve, perfect for controlling solution temperature on a hot plate.

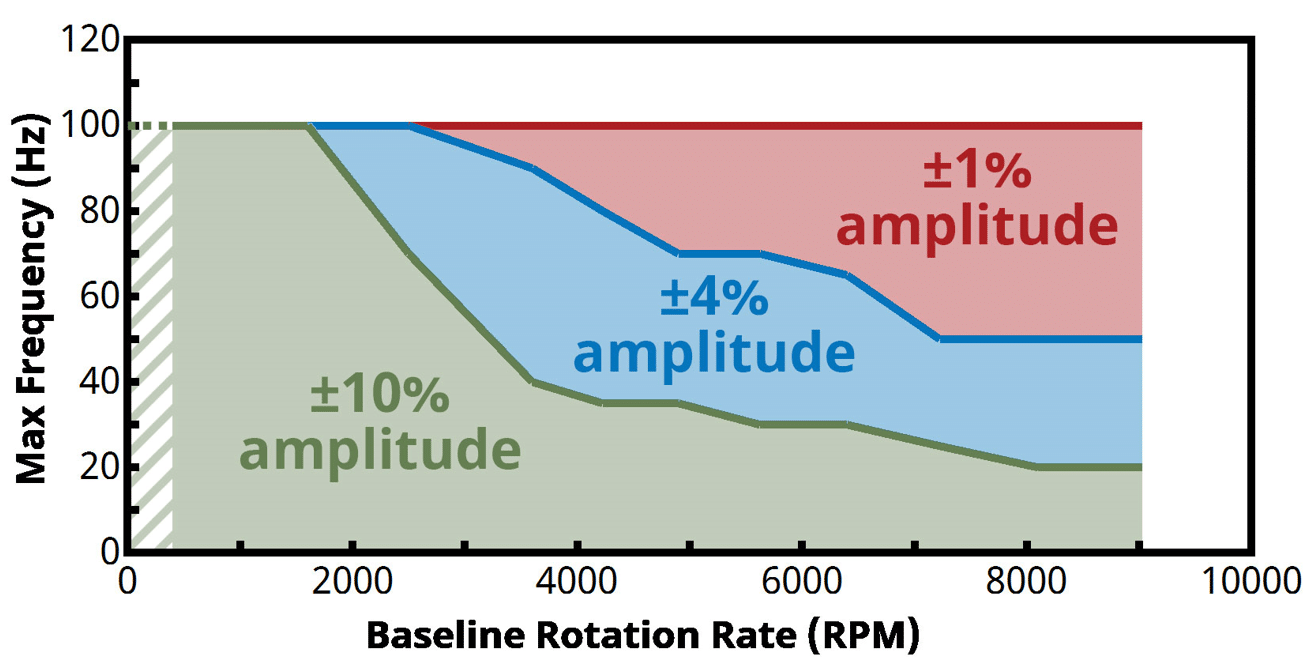

The 15 mm OD Rotating Cylinder Electrode (RCE) system features a number of improvements over previous designs which will assist you in your high velocity (high shear) corrosion testing. The larger 15 mm diameter gives you more wall shear at the cylinder surface at a given rotation rate (as compared to the traditional 12 mm OD design).

Insulation. All shaft components are fabricated from a chemically resistant polymer (PEEK) to protect the shaft from corrosive attack during testing. At elevated temperatures, this polymer has good mechanical stability as compared to the traditional PTFE-based 12 mm OD design.

One Liter Cell. With an overall one liter capacity, the cell features a removable lid with six flexible side ports. You can equip your cell with a variety of accessories (condenser, pH measurement, thermowell, each sold separately) while still having enough ports for the reference and counter electrode. Cells with drain valves and water jackets are also available.

Alignment. The standard RCE glass cell features a special recess in the bottom of the cell into which the lower end of the RCE shaft is inserted. This recess provides a guide for aligning the shaft along the center line of the cell.

Purging. A dual port purge accessory is included with the cell which permits you to sparge the solution and/or blanket the solution with a purge gas. In addition, the gas-purged bearing assembly, through which the rotating shaft enters the cell, has a separate purge port so that you can maintain a positive purging pressure within the internal space of the bearing itself.

Specimens. The lower end of the electrode shaft accepts 15 mm OD x 6.4 mm tall replaceable cylinder inserts. The nominal cylindrical surface area exposed to the solution is 3.0 square centimeters. Standard cylinder inserts fabricated from a variety of steel materials are offered by Pine Research. Custom inserts fabricated from other materials are available upon request. Alternately, cylinder inserts with the appropriate dimensions may be fabricated by the customer.

Contact. Reliable electrical contact between the shaft and the replaceable cylinder insert is accomplished using a spring-loaded ball plunger which pushes against the inside diameter of the cylinder insert.