Changing Input Rotation Rate on MSR Rotator

Last Updated: 5/30/19 by Neil Spinner

1Background

Modulated Speed Rotator (MSR)

is pre-configured with a ratio of 1.0 RPM/mV because this ratio is compatible with Pine Research potentiostat systems.

Modulated Speed Rotator (MSR)

is pre-configured with a ratio of 1.0 RPM/mV because this ratio is compatible with Pine Research potentiostat systems.

| Input Ratio |

| 1 RPM/mV |

| 2 RPM/mV |

| 4 RPM/mV |

2Changing Input Ratio on MSR Rotator

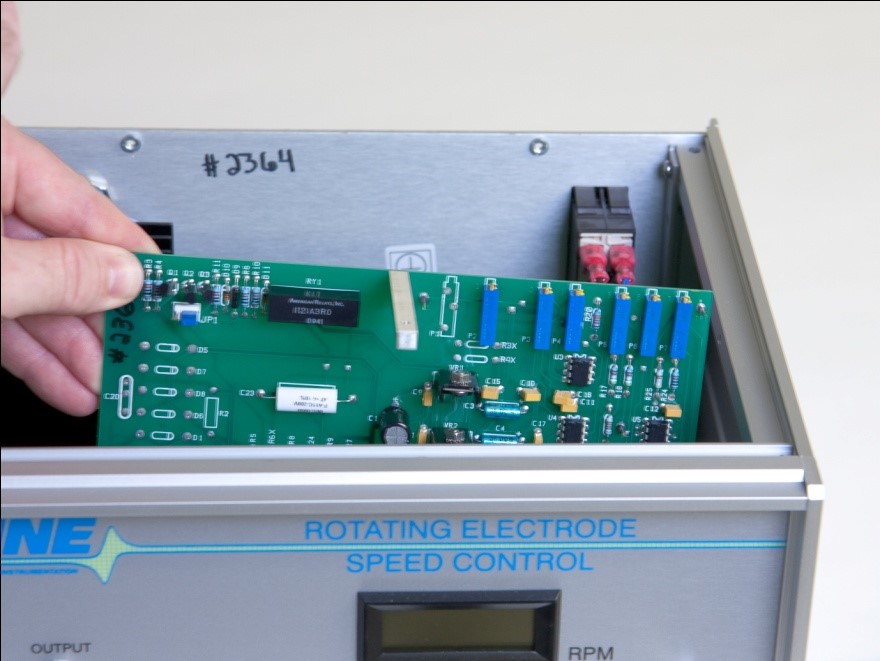

- With the power cord disconnected, remove the cover from the control unit (see Figure 1).

Figure 1. Open MSR Control Unit

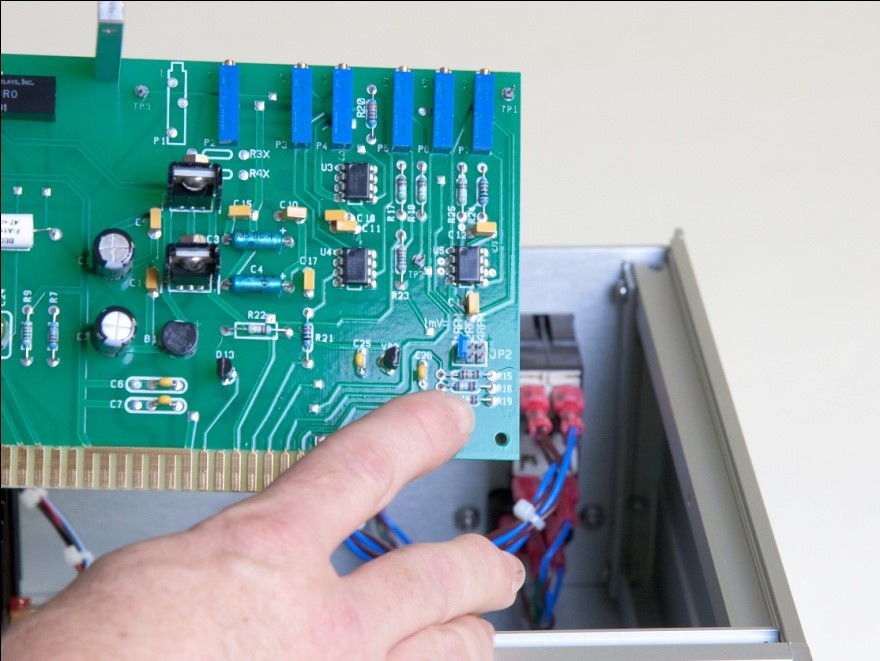

- Loosen the screw that secures the main analog board to the front panel, and then carefully remove the analog board (see Figure 2).

Figure 2. Access the Input Ratio Control Jumpers within the MSR Control Unit

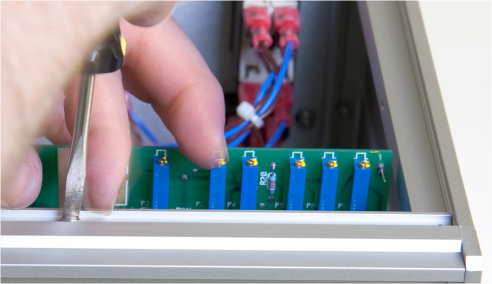

- On the board, locate the configuration pins with the designation JP2. There is a small jumper that can be used to short together one of three pairs of pins (see Figure 3).

Figure 3. MSR Rotator Control Unit Location of Rate Control Jumpers

- Place the jumper across one of the three pairs of pins at JP2. Choose the ratio required for the particular potentiostat being used with the rotator (see Figure 4).

Figure 4. Jumper positions for 1 RPM/mV (Left), 2 RPM/mV (Center), 4 RPM/mV (Right)

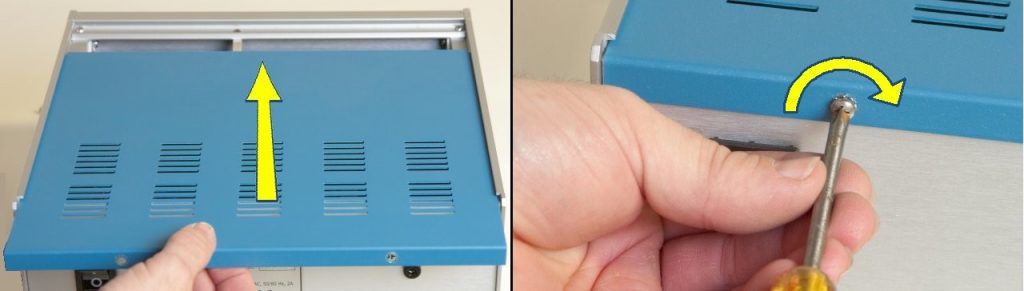

- Reinstall the board in the control unit and secure the board to the front panel (see Figure 5).

Figure 5. Replace Circuit Board into Control Unit

- Replace the cover on the control unit (see Figure 6).

Figure 6. Replace Circuit Board into Control Unit